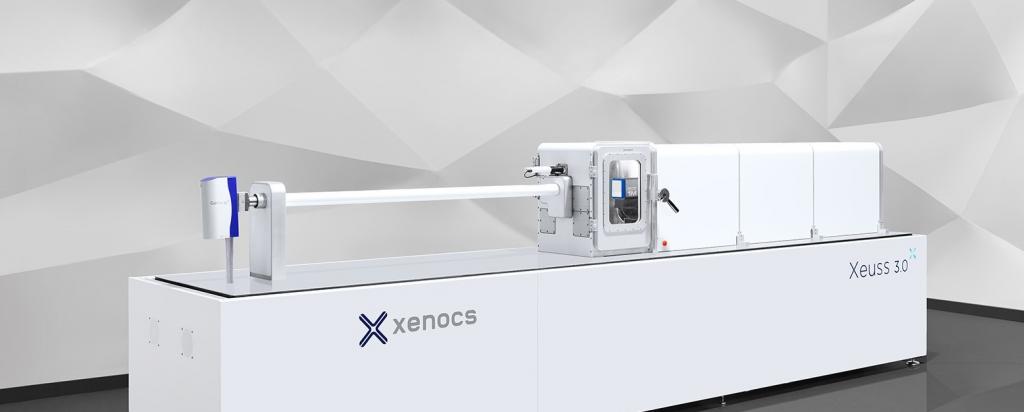

Small angle X-ray scattering instrument

A Xeuss3.0 SAXS instrument (Xenocs Grenoble) has been installed in the ACNS Guide Hall replacing the NanoSTAR II SAXS instrument (Bruker Karlsruhe) which has been in routine operation since 2006. The Xeuss3.0 SAXS instrument will continue to provide scientists with the capability to measure structures of materials from the sub-nanometer to the micron scale. The instrument is equipped with a variety of sample environments and special configurations, including controlled sample temperature, ultra-small angle scattering (USAXS), grazing-incidence geometry (GiSAXS), and measurements under shear.

The system was funded in FY2021/2022 by a RIIP Grant. Access to the Xeuss3.0 SAXS instrument is possible through the ANSTO Research Portal, and the requirement is that the SAXS experiments support SANS/USANS and other neutron scattering experiments. Access for industry-oriented research is facilitated through the ACNS program. Anticipated research to be conducted using this instrument, covers a wide range in soft and hard matter.

Technical Information

Specifications

Instrument geometry | X – horizontal and perpendicular to Y-axis Y – beam axis Z – vertical and perpendicular to Y-axis |

X-ray wavelength | Cu Ka – 1.42 Å Mo Ka – 0.71 Å |

Q-range for Cu Ka wavelength | USAXS Qmin ~0.00015 Å-1 SAXS ~0.002 – ~0.2 Å-1 WAXS <4.9 Å-1 |

SAXS beam dimensions | 150 mm to 1 mm XZ axes; 1.0´1.0 mm2 HI configuration; 0.5 ´ 0.5 mm2 HR configuration |

SAXS beam intensity for Cu Ka wavelength | ~1´108 /sec in HI configuration; ~1.5´107 /sec in HR configuration |

SAXS beam intensity for Mo Ka wavelength | ~5´106 /sec in HI configuration; ~1.5´106 /sec in HR configuration |

Standard capillary size for SAXS | 1.5 and 1.0 mm ID borosilicate glass (or quartz) |

USAXS beam intensity | ~1´106 /sec after monochromator; ~0.5´106 /sec after analyzer |

Absolute intensity scale standard for Cu Ka wavelength | Glassy carbon (NIST SRM 3600) |

SAXS/WAXS Q calibration standard | AgBe and LaB6 (NIST SRM 660b) |

Sample environment, data analysis

Several sample environments are available as standard options (however some are not yet commissioned).

- Multiple refillable capillaries for liquid samples – capillary size 1.5 mm ID borosilicate glass – temperature controlled (-10°C to 80°C) – up to 6 capillaries

- Single capillary for sample under flow – capillary size 1.5 mm ID borosilicate glass – RT only

- Disc-geometry cells for viscous sample – RT only

- ACNS gel cell block (8 positions) – temperature controlled -20 to 150°C

- Multiple capillary holder (9 positions) –capillary size 1.0 and 1.5 mm ID borosilicate glass – temperature controlled -20 to 150°C

- Multiple capillary holder (27 positions) – capillary size 1.5 mm ID borosilicate glass – RT only

- Multiple position holder for powders (14 positions 2.5 mm ID) – RT only

- Multiple position holder for solids (14 positions 5 mm ID; 5 positions 10 mm ID; 4 positions 20 mm ID) – RT only

- Low noise flow cell (LNFC) -temperature controlled (note not presently available because of the high instrument background)

- Couette-geometry shear cell; OD of inner (stationary) cylinder 10 mm; 1mm fixed gap; temperature control ~5° to 120°C. (not presently commissioned 2022).

- Flat plate-geometry shear cell (Linkam CSS450) – temperature controlled ambient to 350°C; shear rate 0.003s-1 to 7500s-1; strain 0.1% to 40,000%. (not presently commissioned 2022).

- Tensile stage (Linkam MFS) tensile force range 0 to 20 N with 0.001 N resolution; tensile speed range 0.1 to 5000 mm; temperature control -150° to 250°C. (not presently commissioned 2022).

Note: that small magnets are used for the convenient location/attachment of several sample environment components which may have an effect on magnetically sensitive samples.

Xeuss3.0 SAXS software simplifies the manipulation of raw data into publication-ready figures.