Space radiation testing for materials and devices

ANSTO offers capabilities and expertise for the radiation testing and accreditation of space-based systems.

Space radiation can affect critical electronic components in space-bound vehicles and satellites. As the failure of any component or system can jeopardize a mission, this risk grows with project complexity and cost. Additionally, space radiation damages material properties and impairs power device performance, making advanced radiation testing facilities essential for ensuring mission success and longevity.

Overview

ANSTO unique infrastructure in Australia provide radiation testing facilities and capabiltiies such as:

- Displacement Damage Dose (DDD) testing using proton beam irradiation.

- Total Ionizing Dose (TID) testing using Co-60 gamma source and x-ray beam irradiation.

- Single Event Effects (SEE) testing using proton, light and heavy ions beam irradiation.

- Pre-screening testing using high intensity synchrotron x-rays to map radiation sensitivity within a single device (proposed Local Ionizing Dose (LID) concept).

- Decapsulation of electronic devices to maximise the simulation of radiation effects.

- GEANT4 Monte Carlo simulation for precise test planning and results interpretation.

- A track record of continuous research in radiation effects in collaboration with Australian universities, Industry, Defence and international collaborators.

- ISO-accredited and secure research sites

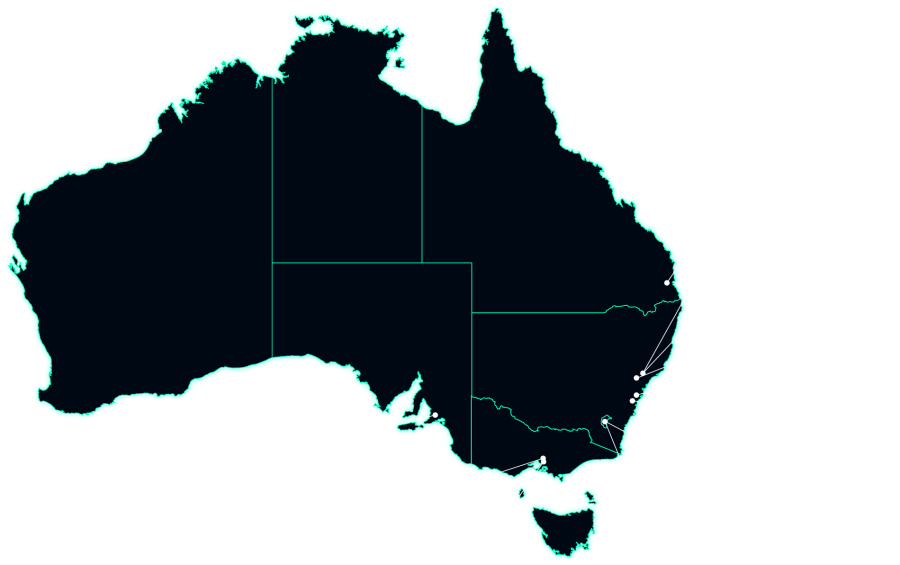

With the National Space Qualification Network (NSQN), you can boost space mission assurance and success through rigorous testing and qualification right here in Australia. ANSTO is a founding partner of the NSQN providing comprehensive radiation testing. For other environmental testings, such thermal, vacuum, shock, laser and for mission design and control, visit the official website.

Contact

CAS Irradiations Team Lead

Dr Stefania Peracchi

Industry Contact

Commercial Technical Consultant